King’s KB series unit heaters are designed for use as primary or supplemental heat sources in large or exposed areas , including high-rise buildings, stores, warehouses, garages, water treatment and fire room vaults to prevent freezing. Spiral finned steel elements and high CFM ensure even air distribution producing cooler element operation, prolonging heater life. By combining the highest quality components, with a dynamically balanced fan blade and in-built thermostat, the KB unit heater will provide years of trouble-free service. Includes universal wall/ceiling bracket for simple installation.

- Adjustable Louvers to Direct Air

- Built-In Fan Delay to Dissipate Heat

- High Mass Steel Fin Heat Exchanger

- Patented Smart Limit Protection®

- Permanent Lubricated Unit Bearing Motor

- Universal Wall/Ceiling Bracket Included

- Proudly Made in the USA with U.S. & Global Materials

- Built-In Thermostat

- 5 Year Limited Warranty

Decades Of Reliability

By combining the highest quality components, with a dynamically balanced fan blade and in-built thermostat, the KB unit heater will provide years of trouble-free service..

Large Exposed Areas Of Comfort

KB unit heaters are Designed for use as primary or supplemental heat sources in large or exposed areas, including high-rise buildings, stores, warehouses, garages, water treatment and fire room vaults to prevent freezing.

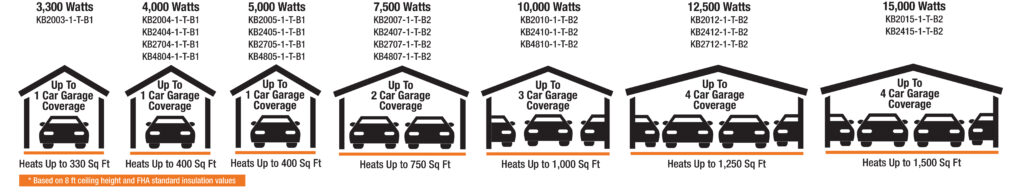

Available Models

Ordering Information

* Dual rated heaters will draw 13% less amps and 25% less wattage when operated at 208V.

** Over 5kw line voltage control is operating the contactor coil only, and will draw under 1 amp.

Ordering Information

* Dual rated heaters will draw 13% less amps and 25% less wattage when operated at 208V.

Field Mount Options

Replacement Accessories

Bracket Selection Chart

Engineering Specs

Contractor shall supply and install KB Series heavy duty unit heaters, manufactured by King Electrical Mfg. Company. Heaters shall be of the wattage and voltage as indicated on the plans.

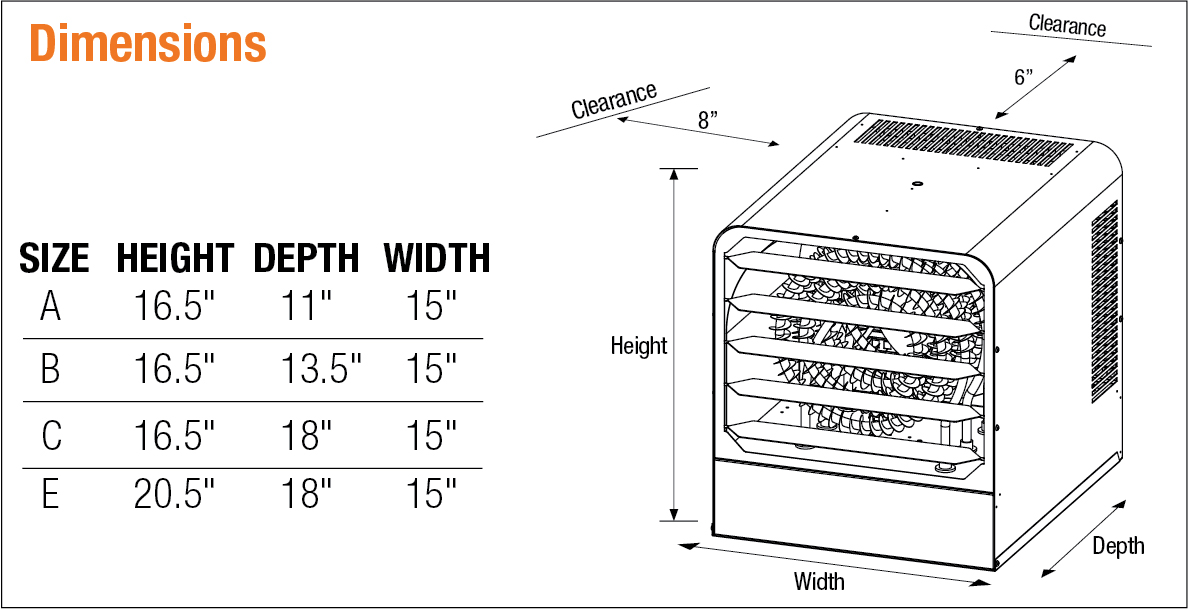

Construction: All exterior and interior metal enclosure parts are made from 20 gauge electrogalvanized Steel with a rust inhibiting baked enamel finish. Smooth rounded corners and protective edge trim give an attractive modern appearance.

Adjustable Outlet Louver: Louvers direct air up or down as needed for the heating application.

Rear Intake Screen: Heavy gauge steel screen protects against foreign objects making accidental contact with the rotating fan blade.

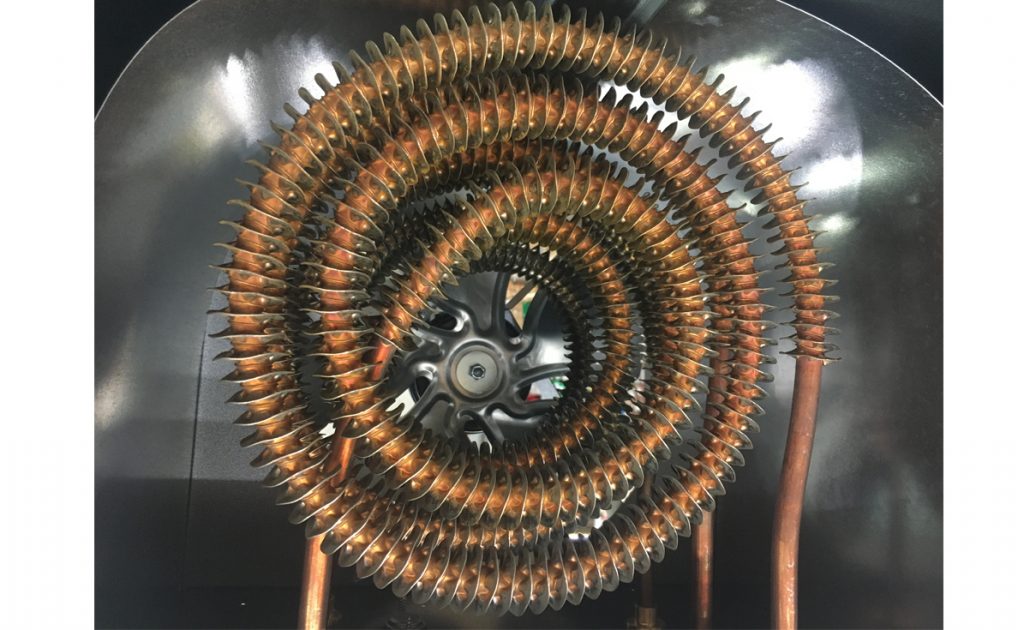

Spiral Fin Elements: The metal sheath element is copper brazed with spiral fins then molded into a coil configuration. This combination produces the best heat transfer while eliminating the potential for hot spots by positioning the element in the maximum airflow stream.

Totally Enclosed Fan Motor: Permanently lubricated long life, unit bearing with 20cc of oil. Epoxy-coated motor with enclosed rotor resists moisture and corrosion for long-lasting, trouble-free operation.

Staging: Two-Stage operation is available as an optional feature.

Aluminum Fan Blade: Axial flow-type mounted directly to the motor shaft for maximum efficiency.

Built-In Thermostat: Single pole factory installed hydraulic capillary tube thermostat for precision heating control. Operating range 40° to 90

Manual Thermal Cutout: Heaters shall be equipped with King’s patented thermal overload Smart Limit Protection®, which disconnects elements and motor in the event normal operating temperatures are exceeded. If thermal overload trips due to abnormal operating temperatures, thermal overload shall remain open until manually reset by turning the heater off for 15 minutes. Automatically reset of thermal overloads, which allow the element to continue to cycle under abnormal conditions, will not be accepted.

Internal Controls: Magnetic contactors are standard on all 480V heaters, all 208V/1-Phase, 240V/1-Phase, 277V/1-Phase heaters above 5kW, and all 3-Phase heaters. The control voltage is equal to the line voltage (208, 240 or 277) except for 480V models where a transformer is provided for 24V control. Over 5kW the line voltage control is operating the contactor coil only and will draw only 1 Amp.

Fusing: Internal circuit fusing is provided when the heater ampacity exceeds 48 Amps to comply with UL standards. A fan delay is provided standard on models 12.5-kW and above to dissipate residual heat from the heating elements.

Easy Installation:A hinged access panel located on the bottom of the heater allows for quick wiring and easy maintenance for the life of the heater. Includes universal wall/ceiling bracket for simple installation.

Approvals: cULus (E41422)