MODEL PKBS

stainless industrial portable unit heater

stainless industrial portable unit heater

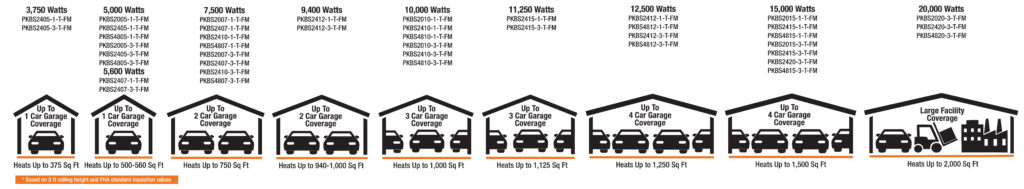

King’s PKBS Stainless Steel Portable Unit Heater is specially constructed for heating of, and freeze protection in, dirty, dusty or corrosive areas requiring periodic washing or hose-down. Typical places of use are: wastewater treatment plants, car/truck washes, agriculture, ship and marine docks, fish processors, and military applications. The heater is constructed from 18-gauge type 304 Stainless Steel and elements making it extremely corrosion resistant. The N.E.M.A. 4 wiring compartment is sealed and gasketed making it watertight. All optional control components are U.L. listed for use in N.E.M.A. 4 enclosures. It is the best heat source to assist in dry-out applications where dry electric heat is preferred over propane or kerosene space heaters. In addition, electric heat has no odor, flame or carbon monoxide. The high CFM and low temperature rise are also key features to make the PKBS the best solution for temporary large capacity heating applications.

These portable stainless heaters are specially constructed for heating of, and freeze protection in, dirty, dusty or corrosive areas requiring periodic washing or hose-down. Typical places of use are: wastewater treatment plants, car/truck washes, agriculture, ship and marine docks, fish processors, and military applications.

Fight mother nature with portable electric heat. A study from Cornell University revealed that increasing the working environment temperature to warmer thermal zones can save employers significant money by reducing errors and improving employee focus. When one company increased working temperatures by less than 10°, the productivity gains amounted to saving 12.5% of their wage costs per worker.

Now That’s Smart!

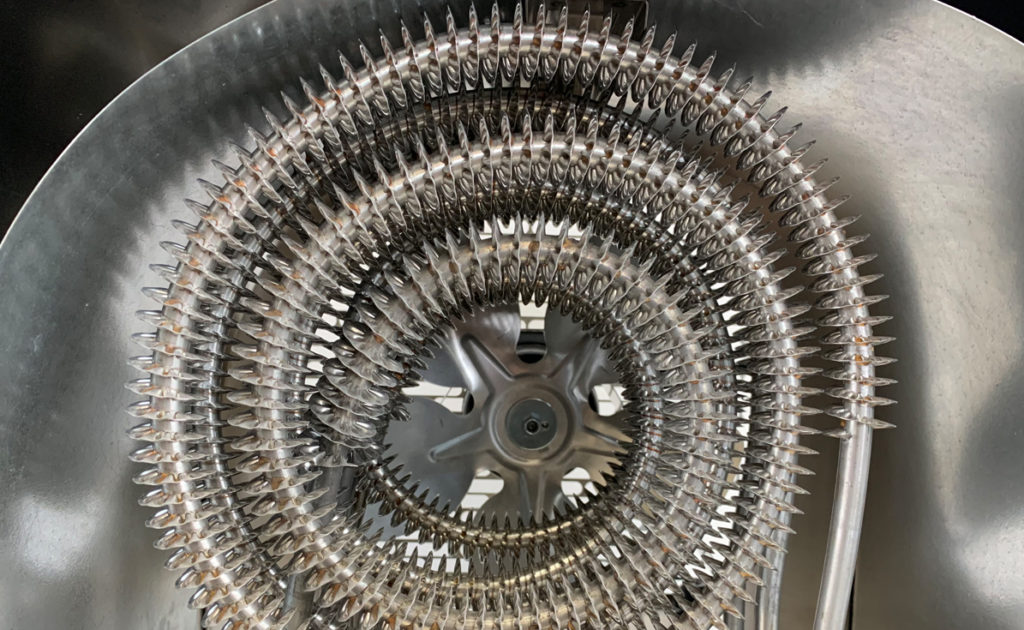

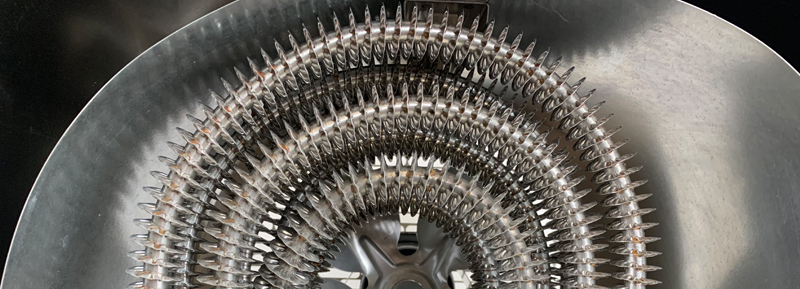

The stainless steel sheath element with spiral fins provides a durable design that produces the heat transfer while eliminating the potential for hot spots by positioning the element in the maximum airflow stream.

* Dual rated heaters will draw 13% less amps and 25% less wattage when operated at 208V. * 2-Stage heating standard.

Contractor shall supply and install PKBS Series electric unit heaters manufactured by King Electrical Mfg. Company. Heaters shall be of the wattage and voltage as indicated on the plans.

Stainless Steel Construction: All exterior and interior metal enclosure parts are made from 18 gauge type 304 Stainless Steel. All fasteners and hardware are Stainless Steel. Smooth rounded corners and protective edge trim give an attractive modern appearance.

Adjustable Outlet Louver: Louvers direct air up or down as needed for the heating application.

Built-in Thermostat: Single pole factory installed hydraulic capillary tube thermostat for precision heating control. Operating range 40° to 100

Fan Only Switch: Comes standard with fan-only switch.

Rear Intake Screen: Heavy gauge steel screen protects against foreign objects making accidental contact with the rotating fan blade.

Stainless Steel Spiral Fin Elements: The metal sheath element is brazed with spiral fins then molded in to a coil configuration. This combination produces the best heat transfer while eliminating the potential for hot spots by positioning the element in the maximum air flow stream.

Totally Enclosed Fan Motor: Permanently lubricated long life, unit bearing with 20cc of oil. Epoxy-coated motor with enclosed rotor resists moisture and corrosion for long-lasting, trouble-free operation.

Aluminum Fan Blade: Axial flow-type fan mounted directly to the motor shaft for maximum efficiency.

Thermal Overload: Heaters shall be equipped with King’s patented thermal overload Smart Limit Protection®, which disconnects elements and motor in the event normal operating temperatures are exceeded. If thermal overload trips due to abnormal operating temperatures, thermal overload shall remain open until manually reset by turning the heater off for 15 minutes. Automatically reset of thermal overloads, which allow the element to continue to cycle under abnormal conditions, will not be accepted.

Cord Length: 6 Foot SO Cord (No Plug Provided)

Approvals: cETLus ( 517271) & (30314521)