KBS unit heaters are specially constructed for heating of, and freeze protection in, dirty, dusty or corrosive areas requiring periodic washing or hose-down. Typical places of use are: waste water treatment plants, car/truck washes, cement plants, steel mills or such, canneries and dairy facilities, ship and marine docks, fish processors and load banks for generators. The heater is constructed from 18-gauge type 304 Stainless Steel and elements making it extremely corrosion resistant. The N.E.M.A. 4 wiring compartment is sealed and gasketed making it water tight. All optional control components are U.L. listed for use in N.E.M.A. 4 enclosures.

- 304 Stainless Steel Construction

- For Areas Requiring Periodic Hose-Down

- Adjustable Louvers to Direct Air

- Permanent Lubricated Unit Bearing Motor

- Patented Smart Limit Protection®

- High Mass Steel Fin Heat Exchanger

- N.E.M.A. 4 Enclosure

- Universal Wall/Ceiling Bracket Included

- UL Certified in Canada & US

- Proudly Made in the USA with U.S. & Global Materials

- 2-Year Limited Warranty

Periodic Hose-Down Requirements. No Problem.

KBS unit heaters are specially constructed for heating of, and freeze protection in, dirty, dusty or corrosive areas requiring periodic

washing or hose-down.

Corrosion Resistant Elements and 304 Stainless Steel

The heater is constructed from 18-gauge type 304 Stainless Steel and elements making it extremely corrosion resistant. The N.E.M.A. 4 wiring compartment is sealed and gasketed making it water tight. All optional control components are U.L. listed for use in N.E.M.A. 4 enclosures.

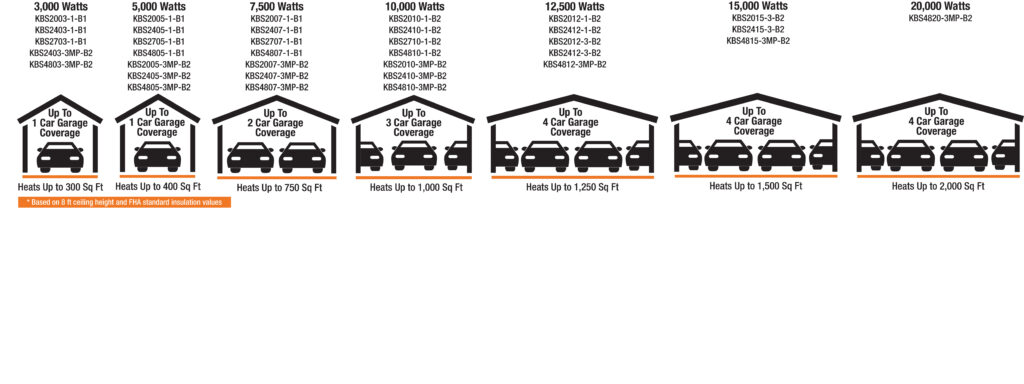

Available Models

Ordering Information

Maximum mounting height is manufacturer’s recommendation *Dual rated heaters will draw 13% less amps and 25% less wattage when operated at 208V.

** Factory set with provision for 24V Remote Thermostat ( purchased separately)

Accessories

Engineering Specs

Contractor shall supply and install KBS Series Stainless Steel heaters, manufactured by King Electrical Mfg. Company. Heaters shall be of the wattage and voltage as indicated on the plans.

Stainless Steel Construction: All exterior and interior metal enclosure parts are made from 18 gauge type 304 Stainless Steel. All fasteners and hardware are Stainless Steel.

Adjustable Outlet Louver: Stainless Steel louvers direct air up or down as needed for the heating application.

Rear Intake Screen: Heavy gauge Stainless Steel screen protects against foreign objects making accidental contact with the rotating fan blade.

N.E.M.A. 4 Enclosure: Every electrical component in the wiring compartment is sealed with a polyurethane adhesive. The bottom access panel is sealed with a 1⁄4″ high density polyurethane gasket. This provides excellent protection against corrosion, windblown dust, dirt, and rain, splashing water and hose-directed water. All optional control accessories are N.E.M.A. 4 rated.

Stainless Steel Spiral Fin Elements: The metal sheath element is brazed with spiral fins then molded in to a coil configuration. This combination produces the best heat transfer while eliminating the potential for hot spots by positioning the element in the maximum air flow stream. Stainless steel increases element life in extremely corrosive environments such as waste water treatment plants.

Totally Enclosed Fan Motor: Permanently lubricated, long life unit bearing coated motor with enclosed rotor resists moisture and corrosion for long-lasting, trouble-free operation.

Aluminum Fan Blade: Axial flow-type mounted directly to the motor shaft for maximum efficiency.

Manual Reset Limit Electrically Held: Power is disconnected from the heater if an overheated condition occurs. The heater is re-energized automatically when the normal operating temperature returns.

Internal Controls: Magnetic contactors are standard on all 480V heaters, all 208V/1-Phase, 240V/1-Phase, 277V/1-Phase heaters above 5kW, and all 3-Phase heaters. The control voltage is equal to the line voltage (208, 240 or 277) except for 480V models where a transformer is provided for 24V control. Over 5kW the line voltage control is operating the contactor coil only and will draw only 1 Amp.

Fusing: Internal circuit fusing is provided when the heater ampacity exceeds 48 Amps to comply with UL standards. A fan delay is provided standard on models 12.5-kW and above to dissipate residual heat from the heating elements.

Approvals: cULus